Best-in-practice advanced test packages have been established in two ASTM methods: ASTM D4378, "Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam, Gas, and Combined Cycle Turbines" and ASTM D6224, "Standard Practice for In-Service Monitoring of Lubricating Oil for Auxiliary Power Plant Equipment".

We highly recommend going beyond the first level of oil analysis condition monitoring by incorporating our Premium Program advanced testing package. Together we help our clients finalize the list of lubricants to include in the Premium Program.

There’s a difference in the test package, depending on the type of equipment, the chemistry of the lubricant, and the optimal time between oil changes. MRT also offers comprehensive compatibility testing for lubricating oils.

| Every 6 Months | ASTM Procedure | Usefulness |

|---|---|---|

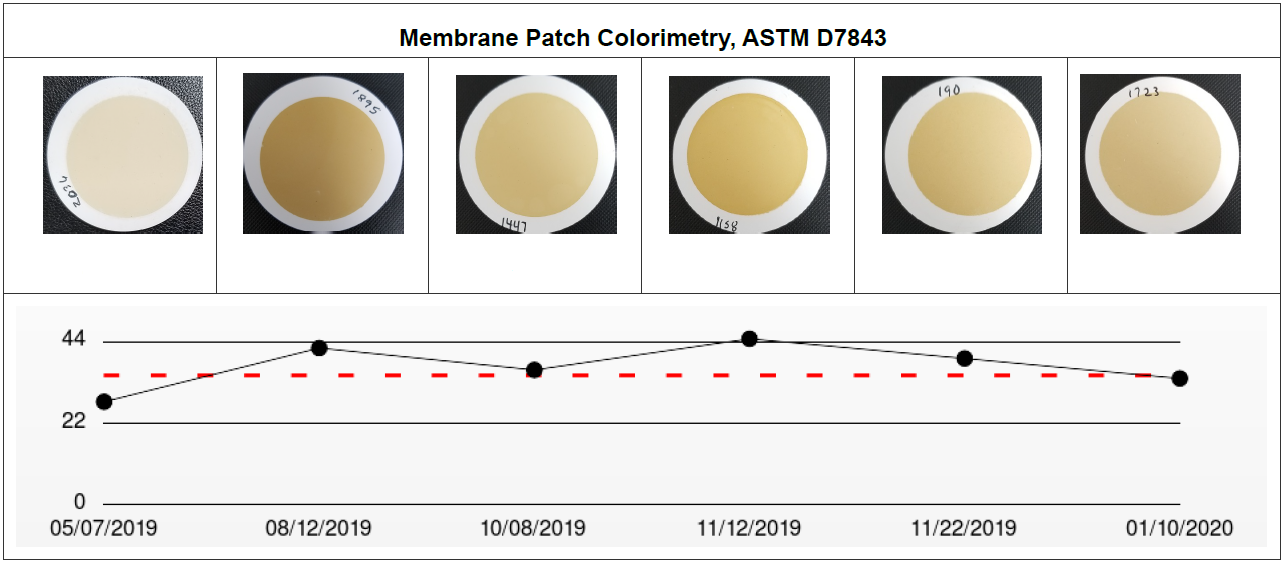

| Membrane Patch Colorimetry | D7843 | Varnishing potential, soluble contaminants |

| Ultra Centrifuge | - | Varnishing potential, insolube contaminants |

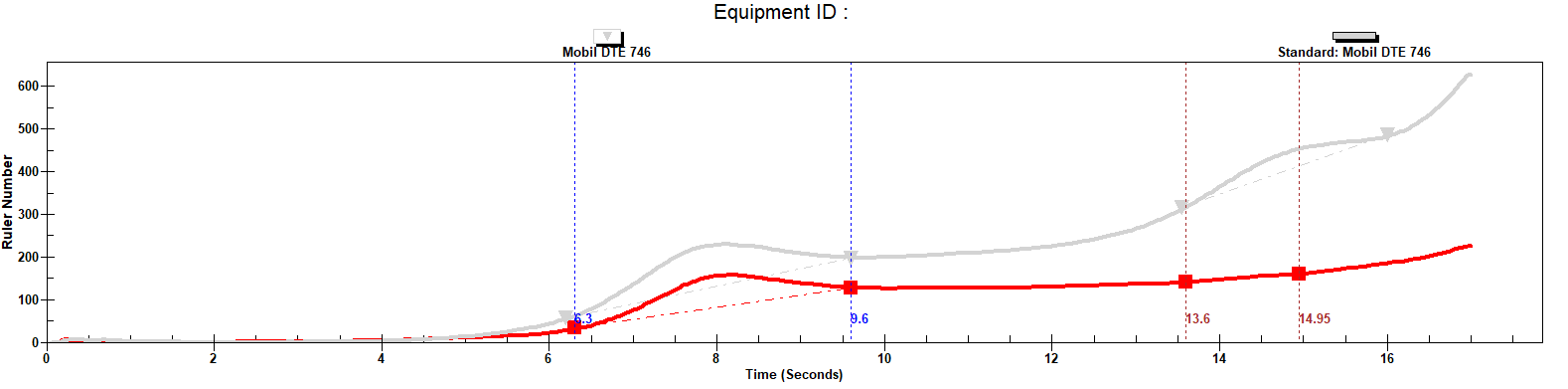

| RULER | D6971 | Remaining useful life of the lubricant | Every 12 Months | ASTM Procedure | Usefulness |

| Water Separability | D1401 | Release water, prevent oxidation |

| Air Release Characteristics | D3427 | Release entrained air, prevent oxidation/wear |

| Foaming Characteristics | D892 | Dissipate foam, maintain lubrication |

| RPVOT | D2272 | Remaining useful life of the lubricant |

| Rust Prevention | D665 | Prevent rusting by water contamination |