Oil analysis is the most cost-effective tool in a condition monitoring program of critical mechanical equipment. We test all industrial lubricants, hydraulic fluids, and engine oils of any brand and any chemistry. We maintain an enormous library of baseline comparison data to support whether oil analysis testing results are normal or out of specification.

The greatest value of an oil analysis report is detecting abnormal equipment wear at its earliest stage. Our success is being the first to inform you of an early stage issue. Vibration and temperature monitoring are also imperative to a successful condition monitoring program – complimenting the oil analysis by monitoring an issue as severity increases over time.

On every laboratory report we offer the optimal set of tests to assess the condition of the lubricated equipment, the condition of the fluid, the nature of any contamination, and the overall assessment. We guarantee an informed assessment of whether abnormal wear is detected, whether the fluid is suitable for continued use, and whether fluid contamination is promoting adverse lubricating conditions in the unit.

To properly detect abnormal wear of rotating equipment at the earliest stage, oil analysis must be done frequently and consistently in an organized manner. The most critical equipment should be tested monthly. Over time, good oil analysis results and lower maintenance costs will dictate whether the sampling schedule can stretch to less frequent intervals. Occasionally a new client will ask whether testing at six-month or even annual intervals is adequate. We put the question back to them, “If abnormal wear begins one month after the last check-up, is it okay that it continues for another five months until testing again?” Almost always the answer to that question is ‘No’.

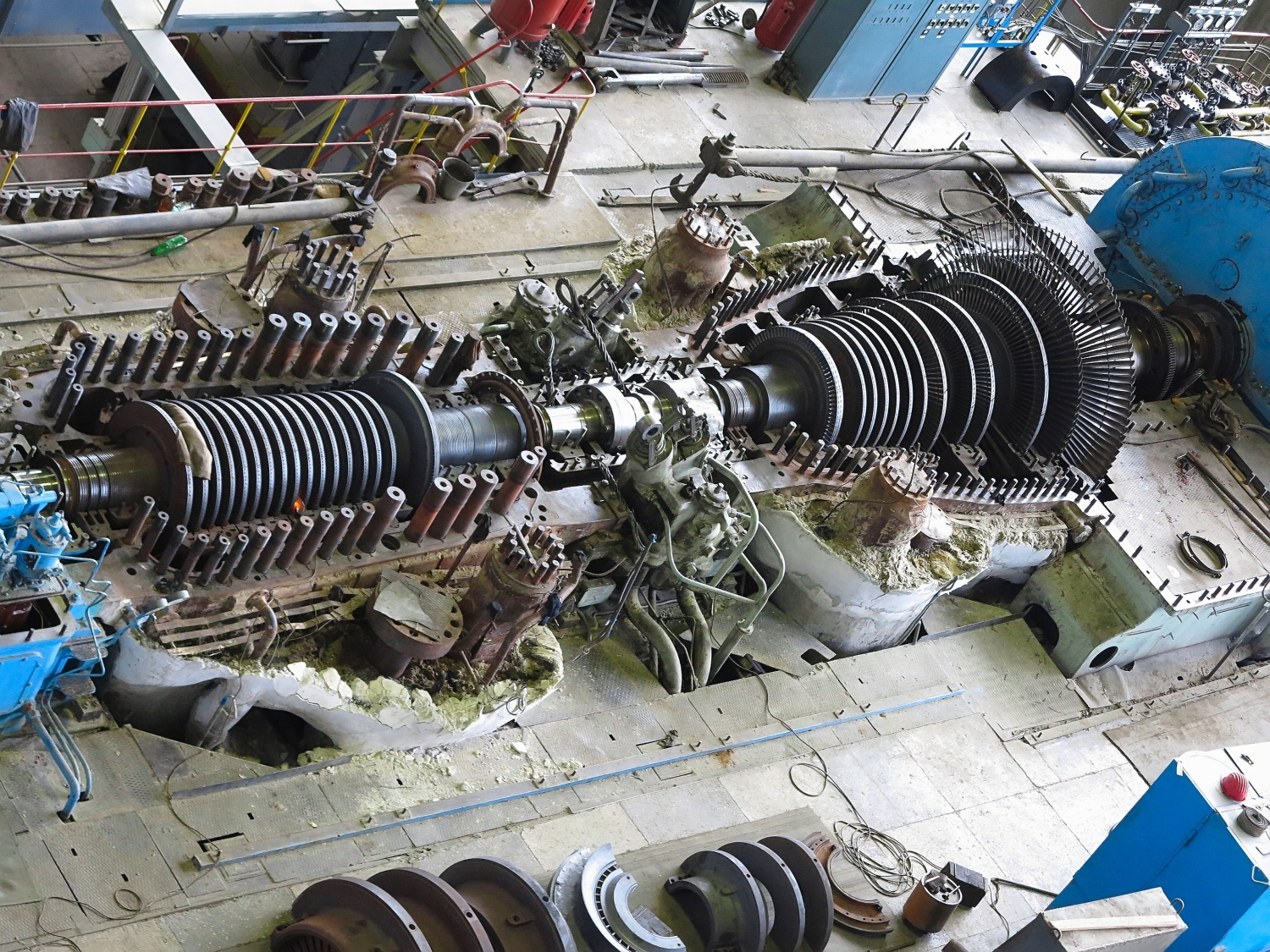

MRT has extensive experience with all major equipment types. From crankcases in reciprocating compressors to proportional valves in automobiles, we we always strive to take the specific needs of the application in mind when providing counsel.

(Click on Images for More Info)

Take The Next Step.